In aerospace and defense applications, failure carries consequences that extend far beyond damaged equipment. A single breakdown can jeopardize missions, weaken security, and put lives at risk. Systems operating in these environments are subjected to relentless and overlapping stressors, including extreme temperatures, sudden shock events, intense pressure changes, corrosive exposure, and sustained vibration. Unlike commercial systems, military-grade hardware must withstand all of these forces at once. Engineering for aerospace and defense extremes means developing solutions that maintain accuracy, stability, and performance even under the most punishing conditions.

Engineering at the Edge of Capability

Mission-critical design starts with intent, not materials. Whether a system is built for hypersonic travel through the upper atmosphere or for operation under immense ocean pressure, engineers begin by asking a fundamental question: what is the impact of failure? The answer drives every subsequent design choice, influencing how risk is managed, how fatigue is controlled, and how long-term structural integrity is preserved.

This level of design thinking reaches far beyond reinforcing individual components. Engineers must consider how thermal expansion affects tolerances, how high G-forces influence control mechanisms, how salt and moisture degrade exposed surfaces, and how electromagnetic interference can disrupt data transmission. Addressing these challenges requires advanced modeling, multiphysics testing, and careful coordination across subsystems. Sealing solutions must perform through rapid temperature swings and pressure shifts. Connectors must remain secure under constant vibration while shielding sensitive signals. Actuation systems must deliver consistent accuracy from storage conditions through peak operational extremes.

Sustained performance also depends on anticipating cumulative stress. Over time, layered stressors amplify wear and accelerate fatigue. Successful engineering accounts for lifecycle durability, modular upgrade paths, and the combined impact of multiple forces acting together. In aerospace and defense environments, performance is measured not only by endurance, but by control, consistency, and precise response under pressure.

Precision Without Excess

High performance in extreme environments does not come from excessive design margins. Weight, space, and power are tightly constrained across defense platforms, making efficiency just as important as durability. Components are expected to achieve more with fewer resources, delivering faster response times, tighter tolerances, and dependable operation as stress levels increase.

This is where aerospace- and defense-qualified systems clearly differ from commercial alternatives. They are not scaled versions of existing products. They are purpose-built, extensively tested, and refined to meet mission assurance standards. Material selection prioritizes stability alongside strength, while structural geometries are optimized to manage vibration, resist radiation, and maintain alignment through repeated launch or deployment cycles.

Above all, these systems are engineered with readiness in mind. Simplified integration, reduced maintenance demands, and long-term availability across evolving mission profiles ensure that performance is reliable when it matters most. In environments where failure is not acceptable, precision engineering becomes the foundation of mission success.

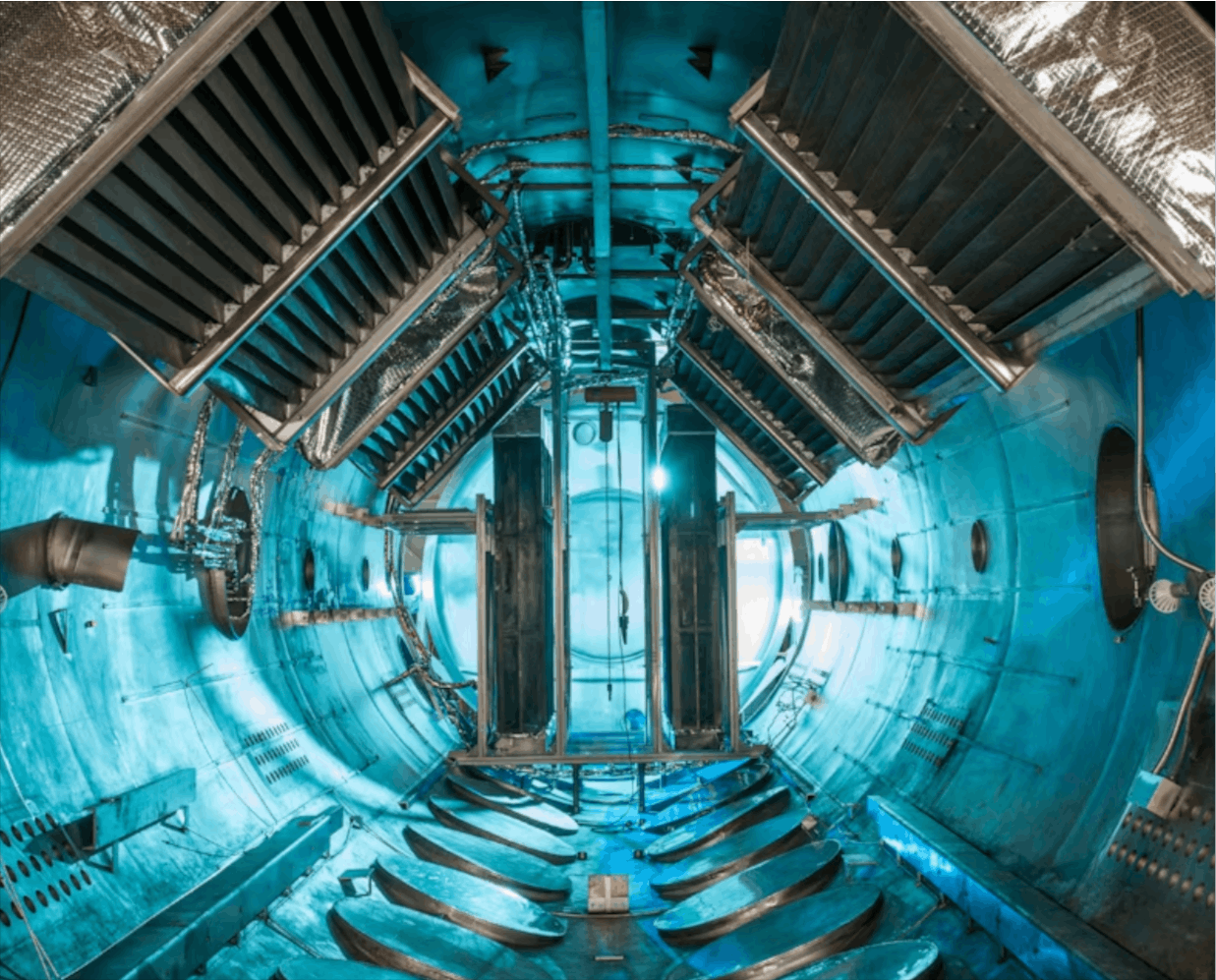

For a deeper look at how engineering enables operational resilience under extreme conditions, view the supporting infographic from Marotta Controls, a solenoid manufacturer.