Have you ever spread a soft, creamy layer of butter on warm toast and wondered about the journey it took from farm to table? The rich, comforting taste of butter has graced our meals for centuries, but the process behind its creation has undergone a remarkable transformation over time. From the quaint, hand-cranked churns of yore to the colossal industrial behemoths of today, butter production has evolved significantly.

In this comparative analysis, we’ll explore the traditional art of butter churning and modern industrial methods, uncovering how each impacts taste, nutritional content, scale of production, and the environment.

The Art of Traditional Butter Churning

The tradition of butter churning dates back to ancient times. However, the method we commonly associate with traditional churning, known as the dash churn, became prevalent from the Middle Ages until the Industrial Revolution. The dash churn comprises a dasher (pole) inserted into the lid of a barrel. This dasher is agitated in a vertical motion, stirring the cream within the barrel to eventually form butter. Even well into the nineteenth century, butter was chiefly made by hand using such churns, which came in various sizes and styles to accommodate different scales of home production.

As simple as it may sound, this method of butter churning held sway for centuries, with the dash churn being the primary method until the advent of hand-crank churns equipped with gears in the mid-1800s. These crank churns, which replaced the simplistic wooden dash churns, dominated American households through the 1940s before being supplanted by electric churns.

The traditional method of churning butter is often revered for the unique taste and nutritional content it delivers. The painstaking manual effort, coupled with the natural fermentation process of the cream, is believed to lend a distinct flavor and a richer nutritional profile to the butter.

The Modern Industrial Evolution

Butter production witnessed a paradigm shift with the advent of modern industrial methods. These methods employ sophisticated machinery to churn butter on a massive scale, meeting the growing global demand. In 2019, U.S. citizens alone consumed 6.2 pounds of butter per person, showcasing a notable 26% increase from 2010.

Today, butter is primarily made from sweet cream, although variations exist, such as those made from acidulated or bacteriologically soured cream. The modern industrial process begins with the aging/fermentation of the milk, much like traditional methods, but what follows is a testament to human ingenuity and the quest for efficiency.

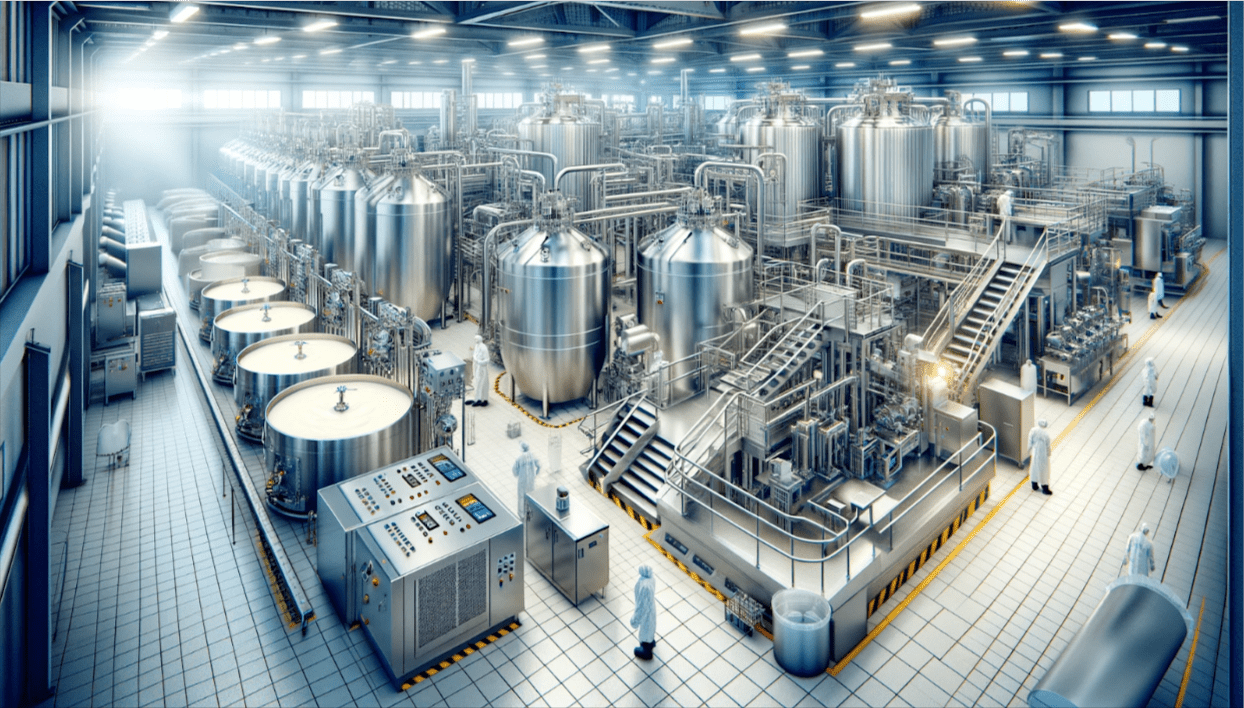

Innovations in technology have birthed custom butter production lines that can churn out vast quantities of butter with minimal manual intervention. Companies design comprehensive butter churn systems that integrate nearly a century of engineering experience, ensuring the accurate and efficient production of butter on an industrial scale

The taste and nutritional content of industrially produced butter may vary from its traditionally churned counterpart due to the scale of production and the ability to control every stage of the process meticulously.

The Blend of Tradition and Technology

In an era where the demand for artisanal and locally-produced goods is rising, some modern producers are finding a sweet spot between the old and the new. They are blending traditional churning techniques with modern technology to offer the best of both worlds. This amalgamation not only honors the rich history of butter-making but also caters to the modern-day emphasis on scalability and efficiency.

For instance, certain producers are utilizing traditional fermentation processes to achieve that distinct, nuanced flavor, while employing modern machinery for churning and packaging. This approach allows for a larger scale of production without compromising the quality and taste that butter enthusiasts crave.

Moreover, embracing technology doesn’t necessarily mean sidelining sustainability. Many modern-day butter producers are investing in eco-friendly practices, such as using renewable energy sources for their operations and implementing waste management systems. This way, they’re not only meeting the high demand for butter but also minimizing their environmental footprint.

Here are some noteworthy practices where tradition meets technology:

– Traditional Fermentation, Modern Machinery: Utilizing age-old fermentation techniques to enrich flavor while employing modern churns and packaging systems for efficiency.

– Local Sourcing, Global Supplying: Partnering with local dairy farms for fresh, quality cream while leveraging modern logistics to distribute butter far and wide.

– Craftsmanship and Automation: Harnessing the finesse of traditional craftsmanship with the precision and efficiency of automated processes.

Conclusion

The journey of butter from a simple dash churn to sophisticated industrial production lines is a testament to human ingenuity and the endless pursuit of perfection. Whether you’re smearing a dollop of traditionally churned butter on your toast or enjoying the fruits of modern production methods, the evolution of butter-making is a rich narrative worth spreading.

Our exploration unveils that each method, traditional or modern, has its unique set of benefits and challenges. While traditional methods offer a rich taste and nutritional profile, modern methods excel in meeting the global demand with remarkable efficiency.