In sectors where accuracy is non-negotiable—like aerospace, food processing, pharmaceuticals, and semiconductor production—true cleanliness requires far more than keeping surfaces spotless. Microscopic particles that can’t be seen with the naked eye are often the biggest threat, capable of disrupting production, damaging equipment, and jeopardizing regulatory compliance. Effective contamination management means looking deeper and addressing risks long before they become visible.

Hidden Sources of Particle Contamination

Routine cleaning, controlled airflow, and filtration systems form the foundation of contamination control, but they don’t eliminate every threat. Mechanical components naturally degrade over time; seals, bearings, and metal fittings can shed particles as they age or operate under stress. These contaminants often go undetected until they begin to affect yield or trigger quality deviations.

Normal movement within the environment can also increase risk. Rolling a cart down a hallway, opening a door at the wrong angle, or shifting equipment between zones can disturb settled dust and redistribute particles into critical areas.

Environmental changes add another layer of complexity. When temperature or humidity rises or falls, condensation can accumulate on overhead structures or HVAC components. As droplets evaporate, they leave behind particles that may fall into clean areas. Electrostatic buildup on packaging materials or synthetic gear attracts fine debris, only to release it unexpectedly during handling.

Even well-engineered HVAC systems can create problems if they’re not optimized. Poor airflow balance or unnoticed stagnation points can cause particles to gather in corners or above equipment, where they remain until disturbed.

Preventing Contamination at Its Origin

Long-term control requires continuous awareness rather than occasional checks. Monitoring particle levels over extended periods allows teams to spot trends—such as contamination spikes following maintenance, workflow changes, or seasonal shifts. Identifying these patterns helps pinpoint root causes and refine procedures.

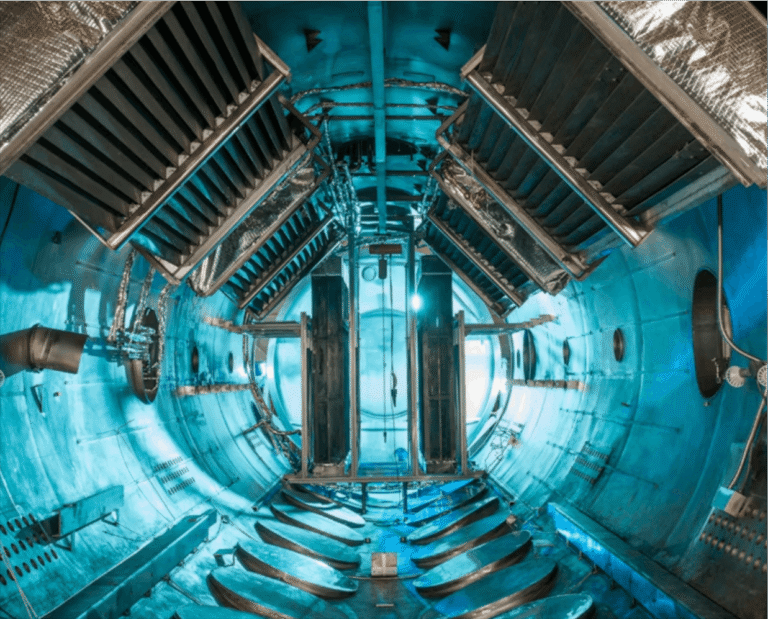

Cleanroom design is another critical defense. Finishes should be seamless, nonporous, and easy to disinfect. Equipment should be engineered for rapid cleaning and minimal particle generation. Reducing crevices and difficult-to-reach areas limits the accumulation of hidden debris.

Personnel practices matter just as much. Protective garments should be low-lint and designed for controlled environments, while gowning protocols need to be reinforced regularly. Establishing uniform hygiene expectations across all teams reduces contamination introduced through human activity.

Maintenance should be carried out with contamination awareness in mind. Tasks like replacing filters, lubricating machinery, or performing inspections should be coordinated between maintenance and operations to safeguard sensitive zones and minimize particle transfer.

From Reactive Cleaning to Predictive Protection

Facilities that shift from “cleaning up after the fact” to anticipating contamination issues build stronger, more resilient operations. Regular airflow testing, ongoing environmental monitoring, and continual training equip teams to prevent issues rather than chase them.

What can’t be seen can still cause significant setbacks. Protecting product quality and ensuring compliance requires looking at contamination from every angle—how it originates, how it travels, and how it can be stopped. With a proactive, data-driven approach, facilities can maintain performance, reduce downtime, and keep even the most delicate production processes running smoothly.

For more on this, check out the accompanying resource from Technical Safety Services, a provider of equipment calibration services.