Contamination risks can arise at any point during pharmaceutical manufacturing, and when they do, the consequences can be serious. Understanding where contamination originates, how to respond when it occurs, and what steps can help prevent it in the future is essential for maintaining safety and compliance.

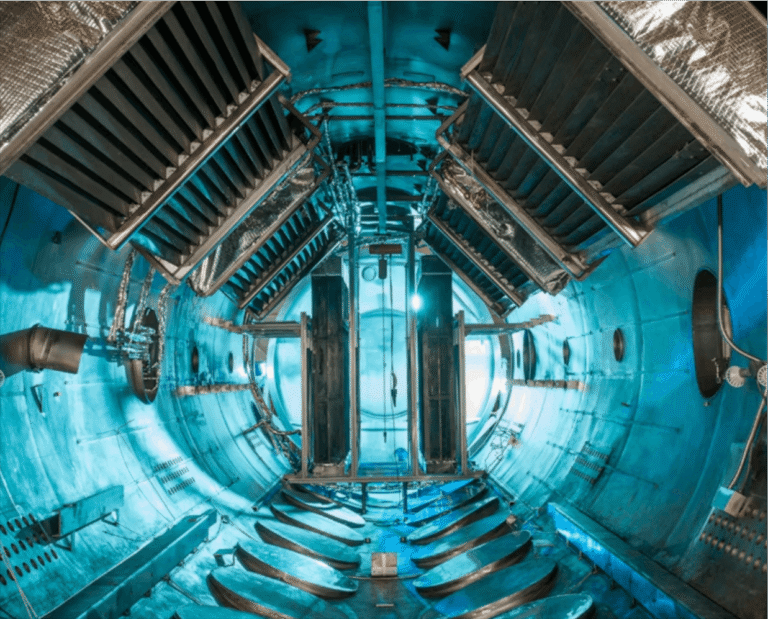

Contamination in pharmaceutical production often stems from breakdowns in microbiological controls. Cleanrooms and laboratories involved in pharmaceutical processes handle a range of hazardous agents—chemical, biological, and sometimes radioactive—making them highly sensitive environments. Any deviation from strict microbiological protocols can compromise product integrity.

Research into FDA enforcement actions reveals that poor microbiological practices are a major contributor to contamination-related recalls. These incidents have affected both sterile and non-sterile drugs. Maintaining tight control of lab procedures and safety protocols is vital to protecting product quality and employee health.

Contaminants can be introduced through numerous pathways. These may include flawed facility layouts, malfunctioning or poorly maintained equipment, improper handling or storage of materials, subpar air filtration, or even basic human error. For instance, when personnel eat or drink in production areas or fail to follow hygiene protocols, they may inadvertently introduce harmful agents into the environment. The misuse or absence of personal protective equipment (PPE) also increases risk.

When a contamination event is suspected, swift action is essential. Comprehensive testing should be conducted immediately to trace the source and assess the extent of contamination. Partnering with certified pharmaceutical testing providers ensures that the response remains within regulatory guidelines. Once the issue is identified, affected areas must be thoroughly decontaminated and revalidated to confirm that safe conditions have been restored.

Moving forward, prevention is the best safeguard. After any contamination event, reviewing and updating prevention protocols is critical. This may include addressing equipment vulnerabilities, adjusting handling procedures, or upgrading air systems and ventilation. Regular audits and improvements help manufacturers maintain high operational standards while fostering a culture of safety and accountability among team members.

By staying vigilant and proactive, pharmaceutical facilities can minimize the risk of contamination, protect product quality, and support long-term operational integrity.