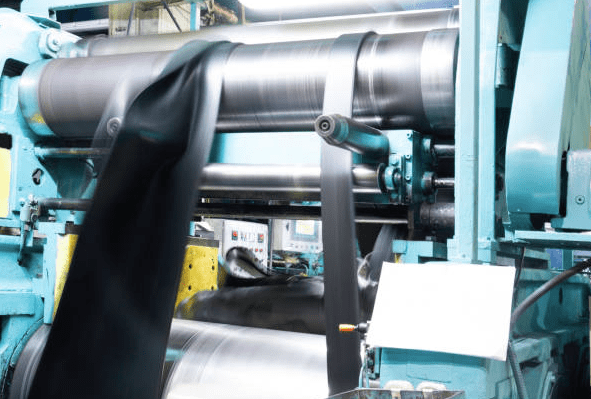

SMC (Sheet Moulding Compound) parts are essential components used across various industries for their exceptional durability, versatility, and reliability. This article will explore the vast array of SMC parts available in the market, such as connectors. These parts are crucial in numerous applications, from automotive and aerospace to electrical and telecommunications. Understanding the diverse range of SMC parts can help you make informed decisions for your specific needs.

Types of SMC Parts:

- SMC: These are vital for establishing secure hydraulic, pneumatic, and electrical connections. They come in various types, including threaded, bayonet, and push-on ones, catering to different requirements.

- SMC Housings and Enclosures: SMC housings and enclosures protect electronic components and machinery. They are known for their robust construction and resistance to environmental factors.

- SMC Panels and Covers: SMC panels and covers are used for shielding and safeguarding sensitive equipment. They offer excellent electrical insulation properties and are often employed in the electrical and electronics industries.

- SMC Brackets and Mounts: SMC brackets and mounts are used to secure components. They are valued for their strength and resistance to mechanical stress.

Materials Used in SMC Parts:

- Fiberglass Reinforced SMC: This material is reinforced with fiberglass to enhance its strength and durability. It is commonly used in applications requiring resistance to impact and mechanical stress.

- Carbon Fiber Reinforced SMC: Carbon fiber-reinforced SMC offers exceptional stiffness and lightweight properties. It is ideal for applications where weight reduction is critical, such as aerospace and automotive components.

- Glass Mat SMC: Glass mat SMC features a layer of glass mat that enhances its rigidity and dimensional stability. It is used in applications requiring precise tolerances and resistance to deformation.

Variations in SMC Parts:

- Miniature SMC Parts: Miniature SMC parts are designed for applications with limited space. They offer compact dimensions without compromising on performance, making them suitable for electronics and medical devices.

- High-Pressure SMC Parts: High-pressure SMC parts are engineered to withstand elevated pressure levels. They are essential in hydraulic and pneumatic systems, where durability and reliability are paramount.

Specialized SMC Parts:

- SMC Valve Bodies: SMC valve bodies are critical components in fluid control systems. They are designed to regulate the flow of liquids or gases in various industrial processes.

- SMC Motor Housings: SMC motor housings protect electric motors from environmental factors and mechanical damage. They are used in applications ranging from industrial machinery to automotive systems.

Customized SMC Parts:

- Custom Molded SMC Parts: Many manufacturers offer custom molding services for SMC parts, allowing customers to design components tailored to their specific needs. Customization ensures that the part meets precise specifications and requirements.

SMC Composite Materials:

- Glass Fiber SMC: Glass fiber SMC is reinforced with glass fibers, providing enhanced mechanical properties such as increased tensile strength and stiffness. It is commonly used in structural applications where strength is a priority.

- Natural Fiber SMC: Natural fiber SMC incorporates natural fibers such as jute or flax into the composite material. It offers environmental benefits and is used in applications where sustainability is a focus.

- Thermoset SMC: Thermoset SMC materials cure through a chemical reaction and are known for their excellent dimensional stability and resistance to high temperatures. They are used in demanding applications like automotive components and electrical insulators.

Advanced SMC Technologies:

- SMC Foam Core Panels: SMC foam core panels combine the strength of SMC materials with lightweight foam cores. These panels offer high stiffness-to-weight ratios and are used in applications such as aerospace and marine industries.

- SMC Composite Tooling: SMC composite tooling is employed in the manufacturing of various composite components. It provides precise and durable molds for producing composite parts with complex shapes and high tolerances.

Specialized SMC Products:

- SMC Electrical Boxes: SMC electrical boxes are non-metallic enclosures used to house electrical components. They are corrosion-resistant and provide electrical insulation, making them suitable for various indoor and outdoor applications.

- SMC Automotive Parts: The automotive industry extensively uses SMC materials for various components, including body panels, bumpers, and interior parts. These parts are lightweight, durable, and offer design flexibility.

- SMC Transportation Solutions: SMC parts play a significant role in transportation solutions such as buses, trains, and trucks. They are used in exterior panels, interior components, and structural elements to enhance fuel efficiency and durability.

The world of SMC parts is vast and diverse, offering solutions for a wide range of industries and applications. Whether you need connectors for secure connections, housings for protection, or insulators for electrical applications, SMC parts provide the durability and reliability required in today’s demanding environments. Understanding the various types, materials, and customization options available empowers you to make informed choices for your specific needs, ensuring that your projects benefit from the strength and versatility of SMC parts.