On-site nitrogen production utilising Pressure Swing Adsorption (PSA) technology has emerged as an essential tool in an era where enterprises are continuously looking for methods to optimise efficiency, cut costs, and improve sustainability.

The Basics of On-Site Nitrogen Generation with PSA Technology

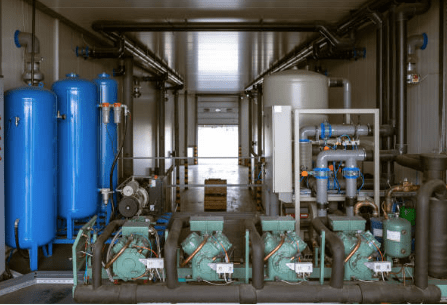

PSA is a frequently used on-site nitrogen-generating method. It works by selectively adsorbing oxygen and other contaminants from compressed air, resulting in a high-purity nitrogen stream. Two adsorption towers loaded with carbon molecular sieve (CMS) material are used in the procedure. While one tower generates nitrogen, the other is depressurized to ensure a constant and uninterrupted nitrogen supply.

Economic Advantages

1. Cost Savings

One of the most significant economic benefits of PSA nitrogen generators on location is the huge cost savings they provide when compared to standard nitrogen procurement techniques. Businesses may save transportation expenses, handling fees, and cylinder rental rates by removing the requirement for bulk nitrogen supplies or reliance on nitrogen cylinders. Furthermore, on-site nitrogen generation eliminates reliance on outside sources, removing the influence of shifting market costs.

2. Operational Efficiency

On-site nitrogen production improves operating efficiency by delivering a consistent and consistent nitrogen supply customised to the application’s exact requirements. Unlike older techniques, which may cause interruptions owing to cylinder delivery delays or supply chain issues, PSA technology assures a consistent and on-demand nitrogen flow. This dependability translates to higher production uptime and a smoother workflow, which improves overall operational efficiency.

3. Customisation for Diverse Applications

PSA technology enables the adjustment of nitrogen purity levels according to the needs of the application. Businesses may fine-tune the nitrogen purity to fit the precise demands of their operations, whether it’s food packaging, electronics manufacturing, or pharmaceutical manufacturing. This adaptability means that the nitrogen created on-site is not only cost-effective but also precisely customised to match the end product’s quality criteria.

4. Energy Efficiency

The PSA technique is notable for its energy efficiency when compared to other nitrogen-generating processes. The process runs at room temperature, eliminating the need for significant heating or cooling. This energy-saving feature equates to cheaper running costs and a less environmental imprint. Businesses can profit not just from cost savings, but also from establishing themselves as environmentally responsible businesses that contribute to long-term goals.

5. Reduced Carbon Footprint

On-site nitrogen production using PSA technology is consistent with the larger push for sustainability. Businesses may dramatically minimise their carbon footprint related to logistics by removing the requirement for nitrogen transportation. Furthermore, the energy efficiency of PSA technology reduces the total environmental effect of nitrogen production. This reduction in carbon emissions may be an enticing element for companies aiming to improve their corporate social responsibility (CSR) programmes and fulfil environmental compliance regulations.

6. Long-Term Cost Predictability

Using external nitrogen providers exposes organisations to market swings and unexpected prices. By allowing enterprises to control their nitrogen production costs, on-site nitrogen generation gives long-term cost stability. This predictability is especially beneficial for companies with limited budgets since it allows for better long-term financial planning and cost control.

Applications Across Industries

Food and Beverage

Nitrogen is frequently used in the food and beverage sector for food packaging, storage, and preservation. On-premises nitrogen generation delivers a steady supply of high-purity nitrogen for modified atmosphere packaging (MAP) applications, prolonging the shelf life of perishable items and maintaining product quality.

Pharmaceuticals

Precision and purity are critical in pharmaceutical manufacture. PSA technology offers pharmaceutical businesses a consistent source of high-purity nitrogen for diverse applications such as blanketing, purging, and inerting, adding to the overall quality and safety of pharmaceutical goods.

Electronics Manufacturing

Nitrogen is commonly utilised in the electronics sector for soldering and reflow procedures. On-site generation guarantees a stable and regulated nitrogen environment, which is critical for avoiding oxidation and guaranteeing electronic component dependability. This is especially significant in the manufacture of delicate electrical products, where accuracy and quality control are critical.

Oil and Gas

Nitrogen is used in oil and gas operations for pressure testing, well-stimulation, and inerting. Nitrogen generation on-site provides the flexibility and dependability required for these essential applications, allowing oil and gas firms to optimise their operations while maintaining safety standards.

Conclusion

On-site nitrogen generation using PSA technology is a breakthrough solution that provides organisations with a strategic edge in today’s competitive and dynamic market. The economic benefits range from customised nitrogen purity to energy efficiency and decreased carbon impact.

PSA equipment stands out as a cornerstone solution as industries across the board seek methods to improve efficiency, satisfy environmental goals, and assure operational resilience. Businesses that embrace this revolutionary technology can not only improve their bottom line but also position themselves as thought leaders.