Technology has changed how we live and work. If you are a manufacturer and want to stay ahead of the competition, then you must keep an eye on the latest technological advancements. One way manufacturers can gain a competitive edge is by utilizing rapid prototyping services. These services bring a lot of benefits that can greatly impact the success and efficiency of the manufacturing process. In fact, the rapid prototyping market has had an average yearly growth of 27% since 2015.

The importance of rapid prototyping services for manufacturers is very important. It enables them to validate designs, test functionality, and gather valuable feedback before investing in full-scale production. This not only saves time but also reduces costs associated with potential design flaws or rework.

In this article, we share more information about rapid prototyping services, so manufacturers can find the best services for their schedule and budget.

What Are Rapid Prototyping Services?

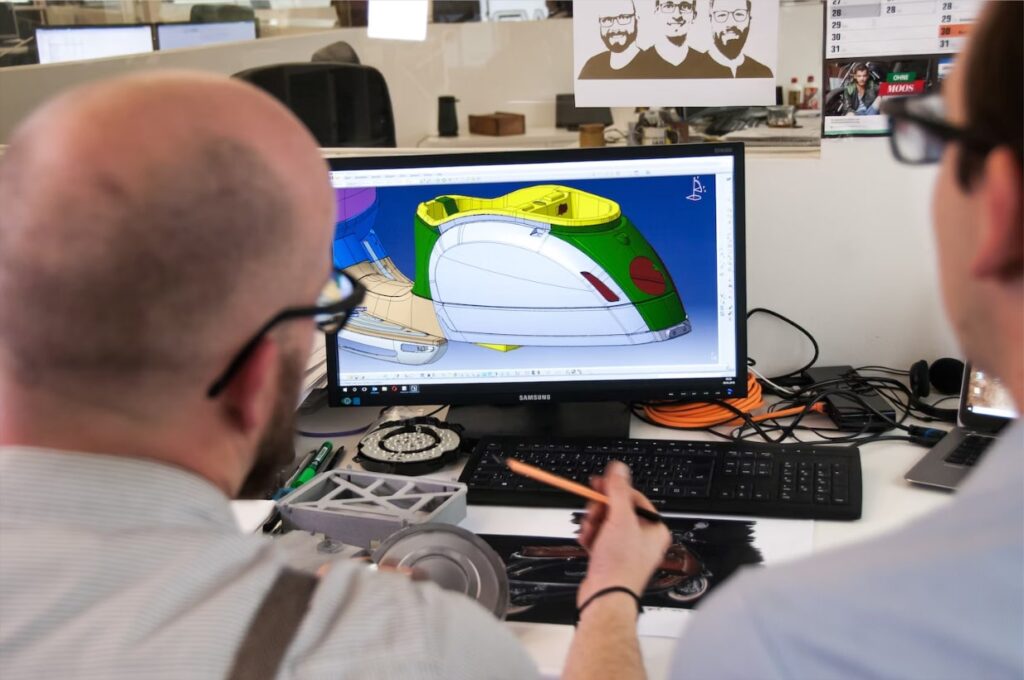

Choosing a rapid prototyping service provider is essential for the modern manufacturer. The process supports sustainable development through the efficient fabrication of physical parts, assemblies, and models. RP is the process of creating a 3D computer-aided design to be used for precision manufacturing. 3D printing is used by many fab shops to quickly produce complex components.

Rapid prototyping companies offer shorter lead times, increased accuracy, and lower operational costs. However, RP requires a significant upfront investment. To determine the best approach, product development teams need to weigh the pros and cons. To make a decision, they can consult with machine operators, engineers, and specialists.

Rapid Prototyping Applications

Rapid prototyping can be used in different ways, so here are some of the most common uses for high-quality rapid prototype services:

- Concept models;

- Visual representations in detail;

- Functional display;

- Previews of pre-production.

Rapid prototyping allows you to create parts or assemblies as well as perfect the blueprint. Keep in mind that you must choose the right technique based on the complexity of your concept and industry standards.

RPS Benefits

Rapid prototyping services offer many benefits that can greatly enhance the product development process. By utilizing advanced technologies and techniques, these services enable businesses to quickly transform their ideas into tangible prototypes. This accelerated timeline not only saves valuable time but also reduces costs associated with traditional manufacturing methods.

Rapid prototyping is a great way to refine and iterate designs quickly. Changing a product’s design in traditional manufacturing can be expensive and time-consuming. However, with rapid prototyping, adjustments can be made swiftly and easily, allowing for faster iterations and improvements.

Another benefit is that you can test and validate your designs before going into full-scale production. By creating physical prototypes that closely resemble the final product, businesses can gather valuable feedback from stakeholders and end-users early in the development process. This feedback can then be used to make informed design decisions, resulting in a more refined and successful end product.

Furthermore, rapid prototyping services allow for greater customization and personalization options. Businesses can easily create prototypes that cater to specific customer needs or incorporate unique features. This level of flexibility not only enhances customer satisfaction but also gives companies a competitive edge in today’s market.

Rapid prototyping services also facilitate collaboration among cross-functional teams. By providing a tangible representation of an idea or concept, prototypes serve as a common reference point for designers, engineers, marketers, and other stakeholders involved in the product development process.

What to Consider When Choosing Rapid Prototyping Services

It can be difficult to choose the right rapid prototyping service, especially if time is an issue. With complex designs, short lead times may not always be possible. Materials also have a major impact on budgeting and scheduling, so it’s important to understand them before you set expectations. Consult your team, but be prepared to discuss the following topics:

Quality Expectations

Are you looking for high-quality prototypes or are you happy with something more basic? Be realistic about your expectations so that you don’t get disappointed if the models come out too simple.

Select a service provider who can deliver high-quality results despite any challenges. It is easier to gain an edge over the competition if you exceed industry standards. Rapid prototyping reduces costs and saves time, even when you pay a lot of money upfront or create multiple models.

Design Complexity

When choosing rapid prototyping, consider the complexity of your design. Some companies are unable to fabricate all components of an assembly themselves. They may have to outsource or improvise. You likely want to reduce costs and streamline the processing by using a single-source provider. To determine the efficiency of your provider, ask them how they do business.

Fidelity

You should consider the look or function of each design. To avoid wasting time and money, it is important to determine the prototype’s fidelity. Low-fidelity prototyping allows for the examination of different design elements, as well as troubleshooting and retooling.

Final Thoughts

The rapid prototyping service can vary greatly depending on several factors. It is important to learn how to distinguish between them. These advanced manufacturing techniques can be used by engineering teams to accelerate product development and reduce production costs. RPS is not suitable for all applications. Prices and timelines are determined by the materials, complexity of design, and provider.