Prolonged UV curing lamp lifespan can enhance the productivity of your printing business. Given that you shell out a significant amount of money for UV curing equipment, it is important you understand different measures you can take to ensure it fits the bill. Before all else, you have to get the UV curing lamp from a reputable manufacturer.

The manufacturer’s specifications can help you determine the lifetime of the UV curing lamp. Additionally, the conditions of your printing facility have a great impact on the durability of the UV curing lamp.

The UV lamp is an essential component of a printing process; it is directly connected to the light intensity and curing times. Old UV lamps might cause you problems like wet UV ink, and weak light intensity. You can tell if a UV lamp has run its course from the indicated replacement period or inefficient curing in which case, you can do the necessary replacement. Let’s dive into some ways you can prolong the lifespan of a UV curing lamp.

Tips On Enhancing the Lifetime of A UV Curing Lamp for Printing

Monitor The Spectral Variation

A key aspect of UV curing lamp maintenance is the spectral output. Different UV Curing lamps offer different spectral outputs, ranging from 100 nm – 460nm. The spectral output is a measure of the lamp’s light intensity, which changes over prolonged use. A change in the spectral output affects the quality of the UV ink cure.

You have to be keen on any changes as they are not too obvious. This will help you take the necessary measures, for example, replacement to ensure you provide your customers with high quality printed products.

Keep To Manufacturers Recommendations

As with any other equipment, UV curing lamps come with some preventative maintenance instructions. They help you understand the correct maintenance chemicals that won’t cause damage. You can use the recommended swabs to get rid of any dust or lint which might cause problems during your printing process.

Regular Cleaning

You should check the UV parts every now and then for any dirt residues. You can clean the lamp weekly; however, how often you clean it depends on the products you are working with, as some generate more ink mist. The following are the cleaning steps:

- Give the lamp a few minutes after printing

- Apply anhydrous ethanol/ isopropyl alcohol to a smooth swab

- Gently wipe the lamp parts repeatedly until clear of all dirt or dust

- Close the covers.

In addition to care for the UV curing lamp, you need to keep your facility clean, as dust from the environment can stick to the equipment’s cavities.

Precaution: Avoid cleaning the UV lamp with water as the wetness can damage and pose a risk of electric shock.

Check for Foreign Matter

Foreign matter will often get on the surface of the UV lamp through your hands. This can happen during the installation of maintenance procedures. Oily palms can cause prints on the UV lamps, which can affect the light intensity.

You can avoid this problem by wearing latex gloves whenever you are handling the lamp. The prints might also eventually cause damage to the quartz material of the UV lamp, especially in high pressure UV lamps.

Conclusion

If you are using mercury lamps in your printing business, you can factor in upgrading to an LED-UV curing system for your printing processes. This will help you eliminate the hassle of constant repairs and replacements. UV curing lamps for printing are easy to maintain.

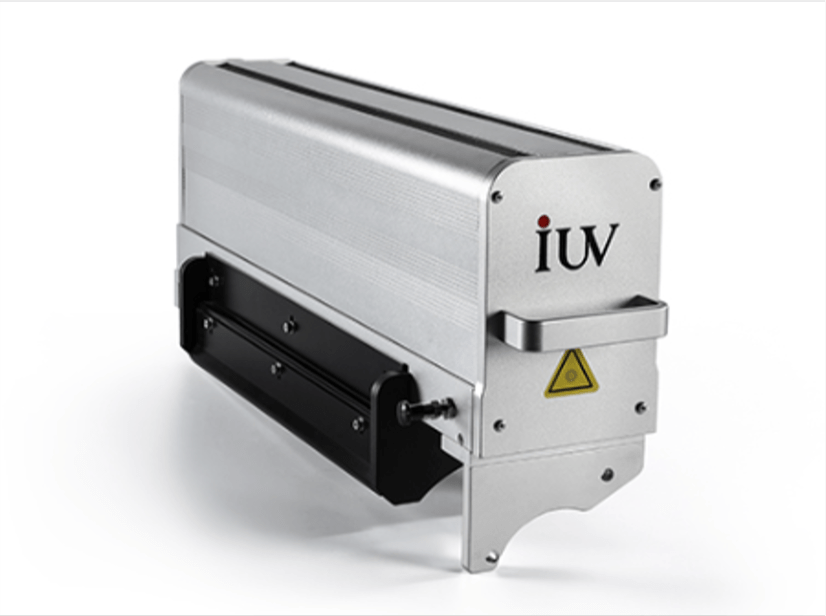

All you have to do is exercise the proper preventative maintenance procedures to enjoy an increased lifetime. IUV is a top-quality UV curing lamp manufacturer. Contact us through a call or email for a prompt quote.