In pharmaceutical and medical device production, contamination is never an isolated issue. It reflects weaknesses across the full manufacturing environment and triggers consequences that touch far more than the batch in question. What may seem like a contained setback often unfolds into operational delays, unplanned spending, and heightened scrutiny that affects the entire organization.

A Cleanup Effort That Extends Far Beyond the Floor

Once contamination is identified, the response process becomes extensive. Investigations must be completed, sanitation intensified, and facility and equipment qualifications reviewed. It is not uncommon for teams to repeat validation steps, reassess environmental monitoring routines, and confirm that every part of the system is working as intended.

These activities take time. They slow or completely halt production schedules, push back release timelines, and disrupt carefully planned workflows. Along the way, the associated expenses — discarded batches, repeated testing, replacement consumables, and extended labor — start to accumulate. For many organizations, these costs stretch budgets beyond what was originally allotted.

Strain Across the Supply Network

Contamination also has a downstream effect on the supply chain. Even when a product’s status is unclear rather than confirmed unsafe, manufacturers may be required to place batches on hold while further testing is performed. These pauses interrupt production rhythm and create bottlenecks that can impact future scheduling.

For products tied to strict delivery commitments, such delays may lead to shortages or missed allocations, placing pressure on healthcare providers who rely on steady availability.

Added Stress on Equipment and Production Assets

Decontamination itself can cause unintended damage. Intensive sanitation methods, strong cleaning chemicals, and repeated sterilization cycles can wear down or degrade production components. Items such as filters, tubing, media, and resins often need to be replaced outright to ensure compliance.

This added strain shortens equipment lifespan and increases long-term maintenance costs, even after operations return to normal.

The Reputational Weight of a Contamination Event

Perhaps one of the most lasting impacts is the hit to credibility. A single contamination incident can prompt increased regulatory attention. Organizations may be asked to implement corrective actions, undergo more frequent inspections, or provide deeper documentation to demonstrate compliance.

Partners, customers, and investors may also question internal processes and overall reliability. Restoring trust takes time and requires ongoing communication, transparency, and evidence of improved controls.

Finding the Root Cause and Strengthening the System

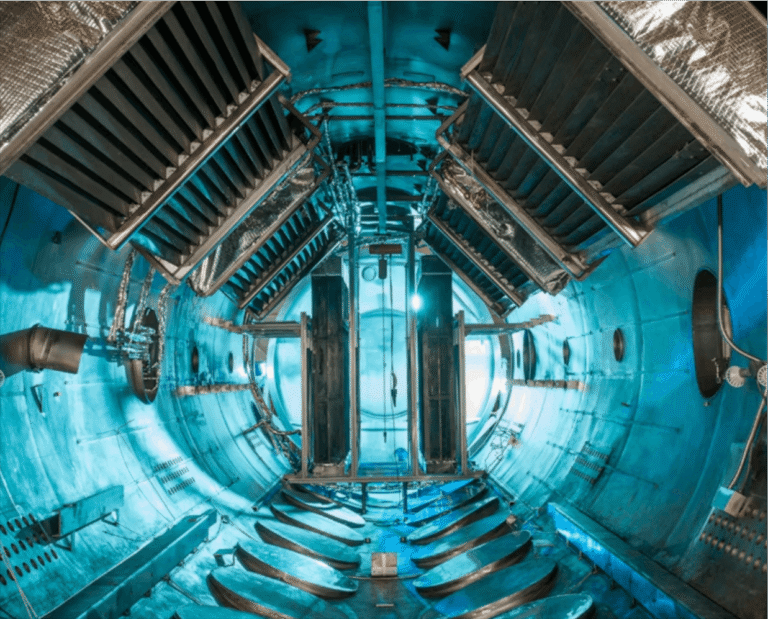

Contamination usually results from multiple contributing factors rather than one clear cause. Identifying and correcting these issues might involve modifying cleanroom layouts, improving airflow systems, upgrading filtration approaches, or reinforcing gowning and aseptic procedures. These improvements require resources, but each change helps create a more stable and predictable production environment.

Prevention as a Strategic Imperative

Real contamination control starts long before an incident occurs. It requires integrated planning, well-designed facilities, consistent training, and a shared commitment to maintaining environmental and process control. In a regulatory landscape that demands reliability, organizations that treat contamination prevention as a long-term strategy protect not only their operations but also the confidence of customers and industry partners.

For more on this, check out the accompanying resource from Scientific Safety Alliance, providers of biosafety cabinet certifications.